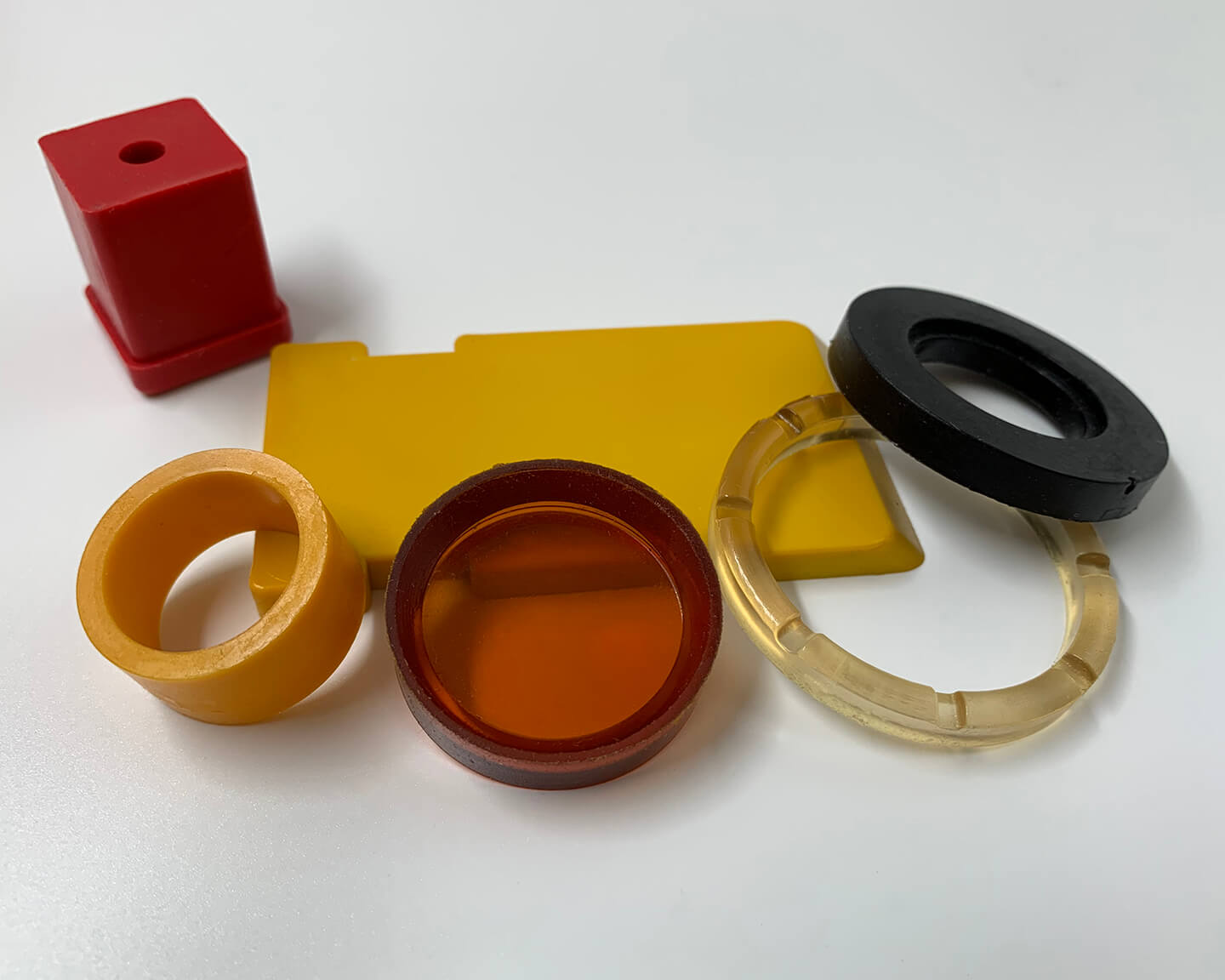

Precision Molding

Polyurethanes (”Urethanes”) are a very versatile elastomer that can be manipulated through chemistry, allowing it to take on a multitude of unique qualities. Polyurethane compounds possess an extraordinary combination of physical, mechanical, and environmental properties. Urethanes bridge the gap between plastics and rubber. The resins can be highly customized to suit your specific needs, particularly the ‘hardness’ or durometer of the material as well as the color.

Did you know you can replace acetal and nylon with urethane in most applications?

Some advantages to using Polyurethane are:

• Excellent resilience

• Extra toughness and durability

• Very high load bearing and cut resistance

• Low compression set

• Very good impact resistance

• Excellent abrasion resistance

• Ability to customize hardness & color

Advantages of Polyurethane Compared to Other Materials:

vs. Rubber

• Higher abrasion resistance

• Higher cut & tear resistance

• Superior load bearing

• Thick section molding

• Colorability

• Oil resistance

• Ozone resistance

• Radiation resistance

• Broader hardness range

• Castable nature

• Low pressure tooling

vs. Metal

• Lightweight

• Noise reduction

• Abrasion resistance

• Less expensive fabrication

• Corrosion resistance

• Resilience

• Impact resistance

• Flexibility

• Easily moldable

• Non-conductive

• Non-sparking

vs. Plastic

• Cost competitive against machined parts

• Lower cost tooling

• High impact resistance

• Elastic memory

• Abrasion resistance

• Noise reduction

• Variable coefficient of friction

• Thick section molding

• Low temperature resistance

• Cold flow resistance

• Radiation resistance

• Ability to mold uneven cross-sections