Quality Elastomers & Foams

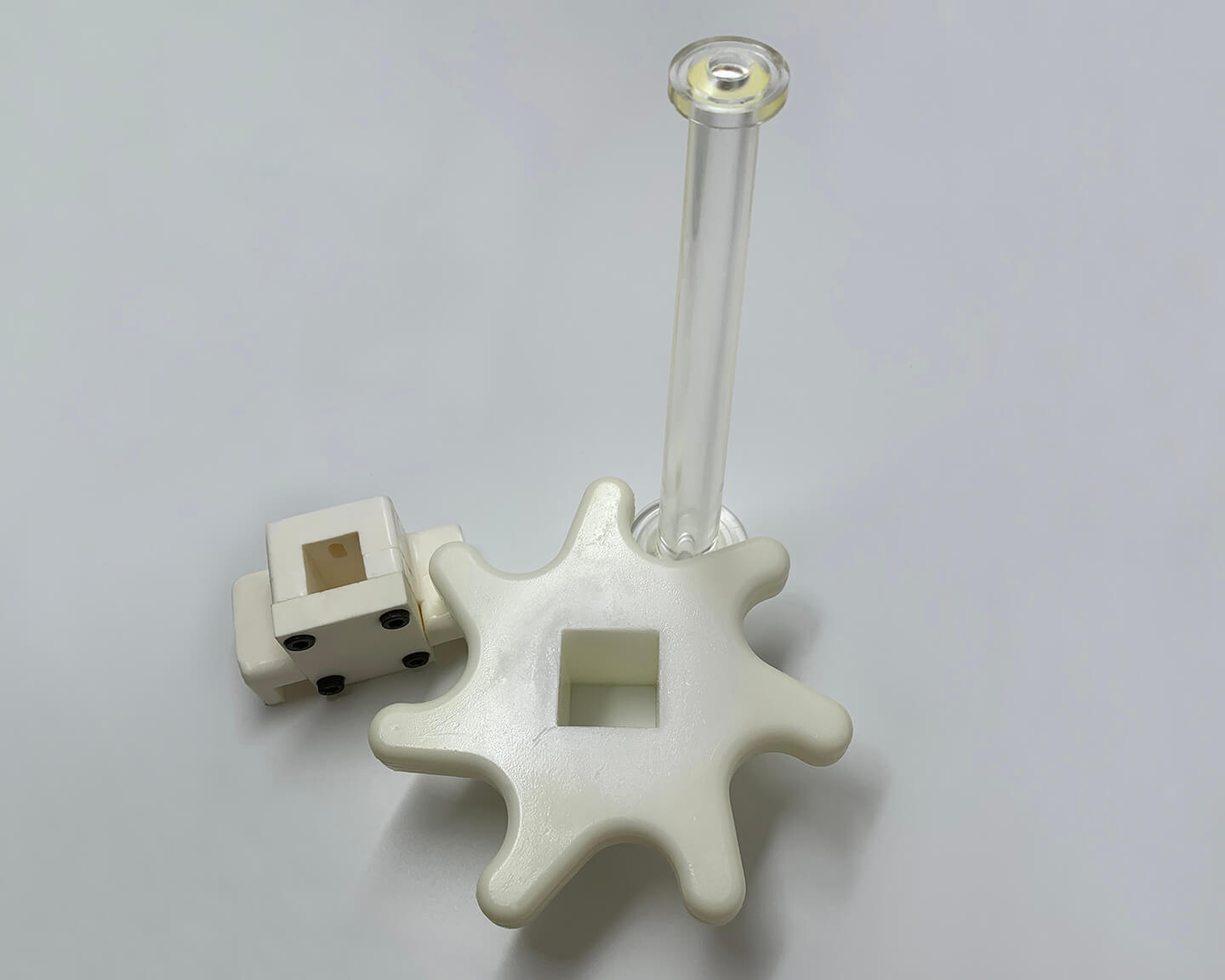

Our specialty is manufacturing molded urethane parts and our experience spans across a variety of techniques and polymers.

Our molding and tool making capabilities can fulfill the entire product life cycle from development to large-scale production, all from a single source.

Capabilities include:

• Reverse engineering

• Material Selection

• Tool Development

• Manufacturing (components, assemblies & finished goods)

• RIM (Reaction Injection Molding)

• Vacuum Forming & Molding

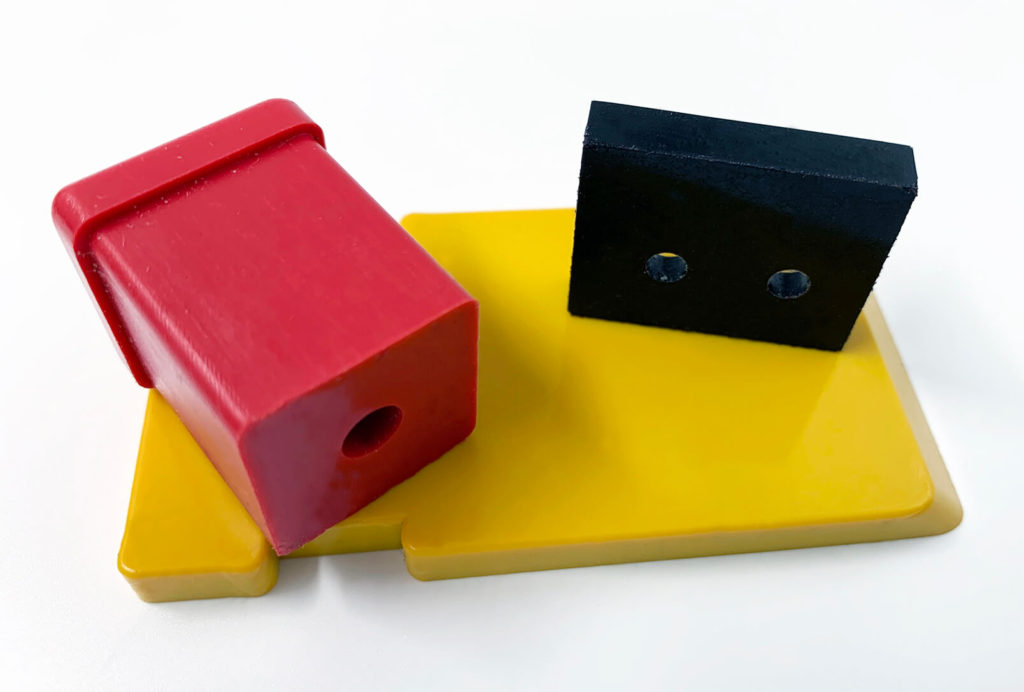

The experts at Hi-Tech can also help develop specific resins and durometers for you based on your application. You can further customize your parts with hardness and color options to suit your needs.

When you need cost effective solutions to your difficult problems, you can trust Hi-Tech to produce top-quality parts at competitive prices. We can produce any part in any quantity – from prototype to production.

Each customer has unique needs, and we have the knowledge, materials and processes to create custom solutions for each one.

Materials to choose from:

Hi-Tech offers a wide range of urethane elastomers and foams, including water clear, FDA-approved and RoHS compliant materials.

URETHANE ELASTOMERS

Molded durometers from A Scale 10A through 95A and D Scale 50D through 80D.

Both Polyether-based urethanes and Polyester-based urethanes material, dual durometers, inserting and pigmenting to color. Specialty materials include FDA approvable filled systems, teflon, bronze, molly and UV inhibitors.

RIGID & FLEXIBLE FOAM

Offering a wide range of density to meet customer requirements. Pigmented to most colors – UL rated systems – ideal for medical and computer panels, P.O.P. displays, architectural and furniture designs. Use for pre-cast insulation inserts and frontals. Excellent surface reproduction from smooth to texture.